Mass Flow Controllers for Inert & Aggressive Gases

High Vacuum and Pressure Applications

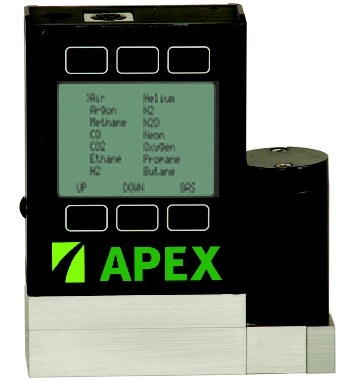

Can Your Mass Flow Controller Control 130 Different Gases?

Apex Mass Flow Controllers for vacuum and pressure applications combine flexibility with outstanding accuracy. Our mass flow controllers are multi-gas capable with a flexibility to choose from a list of up to 130 on-board gases. We offer the option to choose your input and output voltage along with the ability to use RS232 data communications. Using the optional BB9-USB Communications Box, our Apex Mass Flow Controllers can control up to 27 Apex devices through one RS232 port, providing your set-up the ultimate flexibility.

What Makes us Different?

- Multi-Gas Capability - >130 On-Board Interchangeable Gases

- Multiple Control Options- Local on Keypad, Analog, RS-232 all standard

- Addressable RS-232 Digital Control Capability Connect 26 Apex Devices with BB9 Hub

- FlowVision Computer Control/Graphing Software

- Accuracy of 0.2% Full Scale plus 0.8% Direct Reading ( Models 5 sccm or less or above 50 SLPM pr more)

- Accuracy of ±0.6% of reading or ±0.1% of full scale, whichever is greater (Models 10 sccm to 20 slpm)

- High Accuracy Calibration Option of ±0.4% of reading and ±0.2% of full scale (Models 5sccm or greater)

- Steady State Control Range 0.01–100% of full scale

- Flow Ranges from 5000 SLPM down to 0.5 SCCM

- For end users, no power supply/display boxes needed

- RS-232 with software available

- MKS, Aalborg, P-Nucleus, Brooks, Hastings, Sierra & Alicat Pinouts Available for competitor replacement

- High Tech, Low Cost

Additional Informative Links

Applications

- Vacuum Evaporation Coating

- Vacuum Sputtering

- Ion-Beam Deposition

- E-Beam Coating Systems

- Gas Mixing

- High Temperature Furnace Gas Control

- Membrane Testing

- Fuel Cell Research

- Environmental Air Sampling

- Research Applications

Options for Apex Mass Flow Controllers

- TFT Display for low light conditions

- High Accuracy Calibration available

- Remote Display Options

- ATEX designs available on request

- Secondary outputs available

- 0-5V, 0-10V or 4-20 mAmp control standard

-

EtherNet/IP Modbus-RTU (RS-232))

- Modbus-RTU (RS-485)

- RS-485

- DeviceNet, EtherCat, Ethernet IP, Profibus

- Totalizer (No additional Cost)

On-Board Gas Select Screen

Additional Options -

For Display, Special Communication ATEX and other options see the Apex Options

Types of Apex Mass Flow Controllers

Standard, Aggressive and Low Pressure Drop Models

Apex MFC for Vacuum

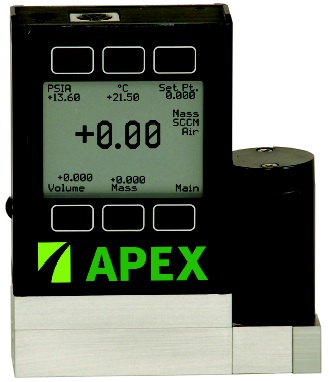

Apex Mass Flow Controller

Our Apex Mass Flow Controller is standard for most applications either vacuum or pressure. At Apex, we offer for the price the most accurate and also fastest MFC on the market. Our available options allow you to customize your mass flow controller to meet your specific needs. These features include high calibration, totalizer function, and custom VCR gas fittings. Our on-board controller allows you to set our MFC without expensive rack mount control boxes. Using our PID parameters, you can further customize the speed and update times to better meet your application needs.

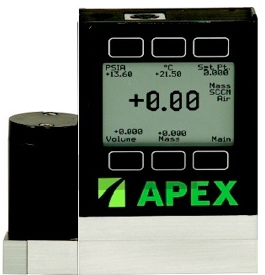

Apex Mass Flow Controller for Vacuum Applications

Our Apex Mass Flow Controller for vacuum applications can be used in new systems or for replacing older mass flow controllers. Replace existing thermal mass flow controllers as ours is comparable form, fit and function. The enclosed valve design and fittings conforms to SEMI International Standards. Gas connections are VCR.

Apex Aggressive Gas Mass Flow Controller

The Apex Aggressive Gas Mass Flow Controller provides flow control of some of the harshest gas applications. Gases include ammonia, butylene, chlorine, dimethylether, hydrogen sulfide, silane and others. The Aggressive Gas Series uses alternative seals compatible with these and other aggressive/corrosive gases that normally are problematic with the standard Viton seals. Each Aggressive Gas Apex MFC comes with all inert and other gases in the library. Output connectors can be the standard NPT or welded VCR.

Apex Low Pressure Drop Mass Flow Controller

The Apex Low Pressure Drop Mass Flow Controller allows control of gas flow when the pressure differential is minimal or cannot be disturbed. This option can reach full-scale pressure drops as low as 0.06 PSID. When you have an application where keeping the pressure differential steady is essential or there is minimal pressure to work with, the Apex Low Pressure Drop Mass Flow Controller is the MFC for you.