RST Operations Video

The RST Vacuum Filter uses a reverse pulse in split second bursts of pressurized air to create a powerful shock to dispel particulate from the filtering element. These pulses cause particulate on the pleated filter element to be discharged and then collected in the drop out area of the filter housing. Pulses can be repeated as required and can even occur during the process due to the minimal effect of the split second air bursts on the process pressure. Operation of the pulsing can be manually controlled or automated based on user preference. (Optional pulse kit available.)

- Ash Handling

- Cement

- Paper Processing

- Pneumatic Conveying Systems

- Vacuum Pumps & Systems

- Woodworking

- Routing Industry

RST Technical Features

- See-through bucket made from shatter resistant polycarbonate material

- High tensile strength permits dimensional stability

- Integrated inlet baffle

- Tap on center of cast head for optional reverse pulse kit air pulse rod:

- 3/8” NPSC tap on 1” sizes, 3/4” NPSC tap on 2 - 4” sizes

- Sturdy swing “claw” bolts clamps bucket to head

RST Options

- Carbon steel bucket (RCT)

- Extended bucket (RSTD)

- Alternate media

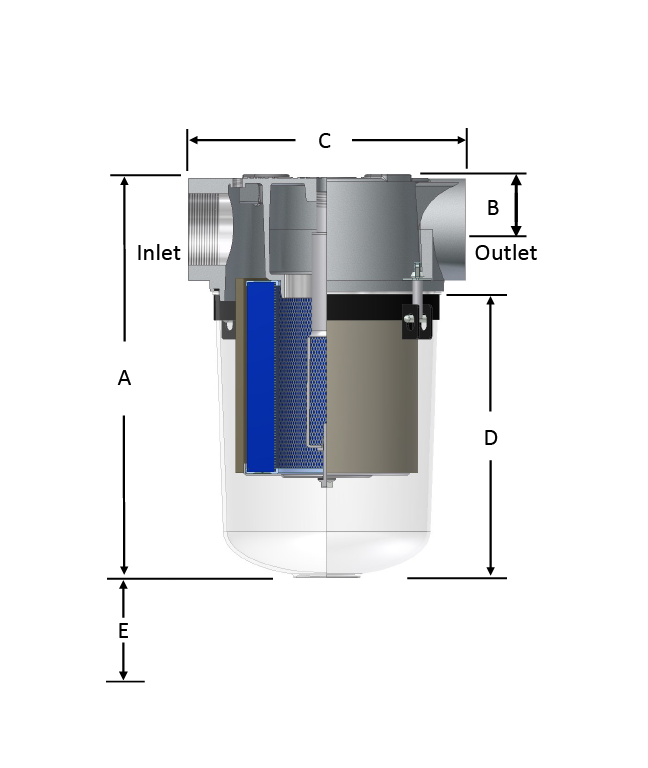

| MODEL | INLET CONNECTION SIZE (IN.) | OUTLET CONNECTION SIZE (IN.) | CONNECTION TYPE | FLOW (SCFM) | DIM A (IN.) | DIM B (IN.) | DIM C (IN.) | DIM D (IN.) | DIM E (IN.) | MEDIA | MICRON RATING | REPLACEMENT ELEMENT |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RST-TF897-100C | 1 | 1 | NPSC | 40 | 13.25 | 1.5 | 7 | 10.25 | 9 | PTFE | 0.3 | TF897 |

| RST-TF897-125C | 1.25 | 1.25 | NPSC | 40 | 13.25 | 1.5 | 7 | 10.25 | 9 | PTFE | 0.3 | TF897 |

| RST-TF897-150C | 1.5 | 1.5 | NPSC | 40 | 13.25 | 1.5 | 7 | 10.25 | 9 | PTFE | 0.3 | TF897 |

| RST-TF851/1-200C | 2 | 2 | NPSC | 145 | 16.25 | 2 | 9 | 12.5 | 9 | PTFE | 0.3 | TF851/1 |

| RST-TF851/1-250C | 2.5 | 2.5 | FPT | 145 | 16.25 | 2 | 9 | 12.5 | 9 | PTFE | 0.3 | TF851/1 |

| RST-TF235-300C | 3 | 3 | FPT | 285 | 19.75 | 2.75 | 13.5 | 14 | 9 | PTFE | 0.3 | TF235 |

| RST-TF235-400C | 4 | 4 | FPT | 285 | 19.75 | 2.75 | 13.5 | 14 | 9 | PTFE | 0.3 | TF235 |