What Makes us Different?

Benefits of the Apex Pressure Controllers include:

- No warm up time

- Pressure ranges from 500 psi down to vacuum pressures available

- Viton Seals

- Tunable PID algorithm

- Turndown ratio of 200 to 1 allowing the controller to measure 1/200 its full scale range

- Analog control but RS232 on each unit for digital control

- 9 units of pressure measurement specified at order

- Digital Display that can be configured to display pressure or flow

- Power can be supplied by connection to wall plug or independent power supply

- NPT connectors but VCR can be supplied

- Operable in flow rates to 2500 slpm

- Operable in very low flow rates

- Lifetime Warranty with yearly calibration

Pressure Control for Pressure or Vacuum

Apex Vacuum Pressure Controllers use differential pressure sensors with a electronic control loop to control the pressure in systems under positive pressure and vacuum. Apex Pressure Controllers can be set up as single or dual valve units. Dual valve units are used in closed volume systems eliminating the need for bleed ports and relief valves.

Our digital pressure controllers provide precision control of absolute or gauge pressure of gases. Units can be employed either upstream or downstream (back pressure control) on the system. Each Apex Pressure Controller is equipped with a digital display that can show pressure in the system or flow. Thus, applications can include leak detection of parts in automobile or medical applications. With update times of 100 milliseconds, the Apex Vacuum Pressure Controller responds quickly to provide smooth pressure steps needed in critical processes.

The Apex Vacuum Pressure Controllers can be used in conjunction with the Apex Mass Flow Controllers and Meters using the BB9 Box. Communication input/output can be user specified with the choices being 0-5V, 0-10V, or RS-232(provided on all Pressure Controllers). No control box is needed for providing power to the unit, just the PVPS24U Universal Power Supply. The on-board display buttons can also be used to set the control pressures.

Additional Informative Links

Types of Apex Mass Flow Controllers

Apex Pressure Controller

Apex Pressure Controller for Millitorr Range

Dual Valve Pressure Controller

High Pressure and Rough Vacuum Pressure Controllers

The 26,000 torr to 760 torr Apex Pressure Controllers are used in a variety of applications where high pressures need to be achieved and maintained. These controllers can be partnered with 1 to 27 other Apex Controllers and Meters to control the amount, speed, and type of gas along with the pressure. Additionally, these units do not need any external sensor.

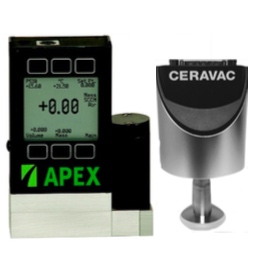

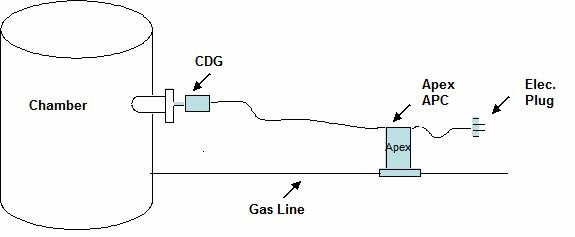

The 4 torr to 760 torr version uses an on-board sensor, while the Apex VPC uses a capacitance diaphragm gauge on the vacuum system to sense pressure. The Apex APC can be used with many CDG’s. Standard models use a 10 torr, 20 torr, 100 torr, 200 torr, or 1000 torr model CDG.

The Apex Vacuum Pressure Controller has a user display to change gases, set the pressure and display readings. The RS 232 interface allows control of 26 individual controllers or meters off one computer RS 232 port. Power up to 27 units with one power cord using the BB9 Box and communications.

Apex Pressure Controllers Millitorr Range

Millitorr Vacuum Controllers

The Apex Vacuum Pressure Controller for the millitorr range uses a capacitance diaphragm gauge as the sensor reading pressure. This linear output gauge sends an analog or digital signal to the Apex Pressure Controller for precise gas control to the vacuum system. The PID loop in the Apex Pressure Controller smoothly controls pressure with updates hundreds of times per second.

Pressure Ranges include 1 torr, 10 torr, 20 torr, 100 torr, 200 torr and 1000 torr ( 3 decades of control...example 1000 torr sensor can control down to 1 torr)

Dual Valve Rough Vacuum Controllers

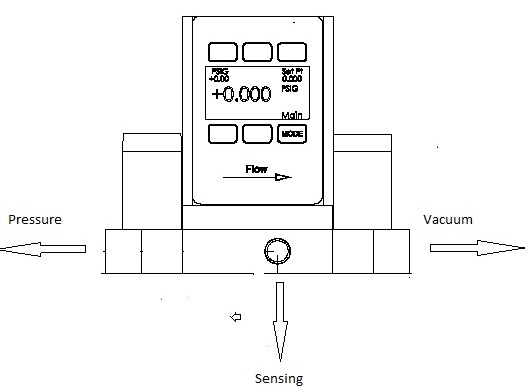

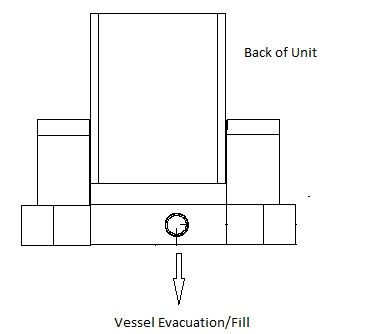

In a dual valve pressure controller one side can be connected to the vacuum pump while other side is exposed to atmosphere or an inert gas source such as nitrogen. The sensing port is connected to the vacuum vessel. The PID in the Dual Valve Controller opens each valve in sequence to hold the pressure steady. The evacuation or filling is carried out in the back of the Controller. (See Diagrams Below)

Dual Valve Pressure Controller Front

Dual Valve Pressure Controller Back

Diagram of Apex Vacum Pressure Controller with CDG Vacuum Gauge

Additional Options -

For Display, Special Communication ATEX and other options see the Apex Options