Apex Mass Flow Leak Detection

Small Device Leak Checking

This diagram shows a small device under test. The Apex Mass Flow Leak Tester utilizes our Apex Low Pressure Drop Flow Controller maintaining a constant pressure to the Device Under Test (DUT) and measuring/displaying the flow rate needed to maintain the pressure in the DUT.

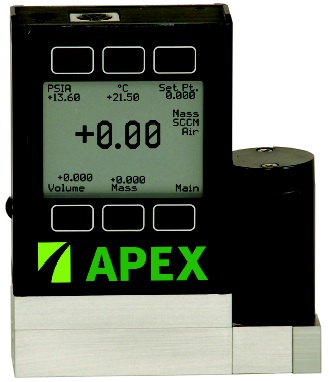

Apex Flow Leak Detector

Pressure decay and mass flow leak detection is the standard leak detection method for many applications especially in the medical and automotive markets. Pressure decay and mass flow systems can be very complex and expensive. With the Apex Vacuum Mass Flow Leak Tester, complexity and cost are significantly reduced while providing very fast, accurate and repeatable leak test results. The Apex Flow Leak Detector opens the door to leak detection with a variety of gases, including air. Find leaks as small as 0.0050 standard cubic centimeters per minute (sccm).

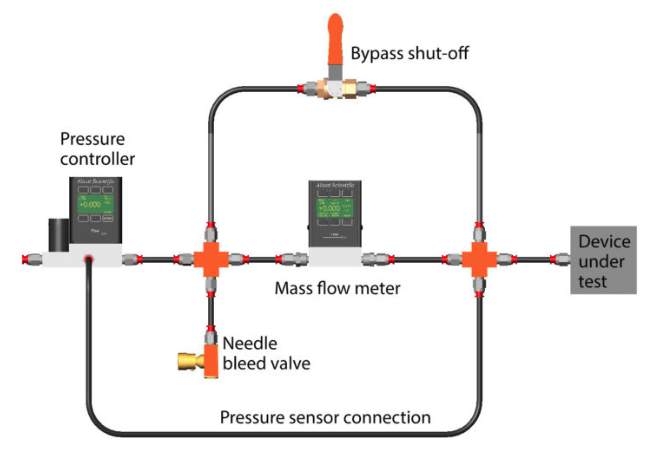

How the Apex Flow Leak Detector Works

In the diagram below, the instruments are the Apex PCD3 Pressure Controller and the Apex Low Pressure Drop Series Vacuum Flow Controller (range to 0.05 SCCM available)

- Choose a specific gas from the 30 gases in the Apex gas library to pressurize your desired test piping or equipment.

- Set the pressure on the Apex Leak Detector to the desired testing pressure and begin flowing gas.

- Once pressure has been reached, monitor the flow. If the piece being tested is leak free, then the flow will equalize at zero once pressure is reached. If there is a leak, to keep that pressure steady the Apex Flow Leak Detector will have a flow value. This flow value is directly proportional to the leak size depending on the pressure being tested at.

Teaming with the Lokring Hydrogen Leak Detector

The Apex Mass Flow Leak Detector finds total leak rate of the closed system but does not identify the leak locations. Using a 5% Hydrogen/95% Nitrogen tracer gas (non-combustible mixture), once the unit is determined to have leaks, the unit can be scanned using our Lokring Hydrogen Sniffer Leak Detector. Leak rates as small as 0.25 oz/yr of refrigerant gas can be identified. Once the leak location is identified, the unit can be repaired and re-tested.