Applications:

Vacuum Evaporation

Freeze Drying

Food Processing

Vacuum Forming

Vacuum Packaging

Lab Analytical Tools

Leak Detection

Roughing Vacuum Systems

Battery Applications

Automotive Parts Applications

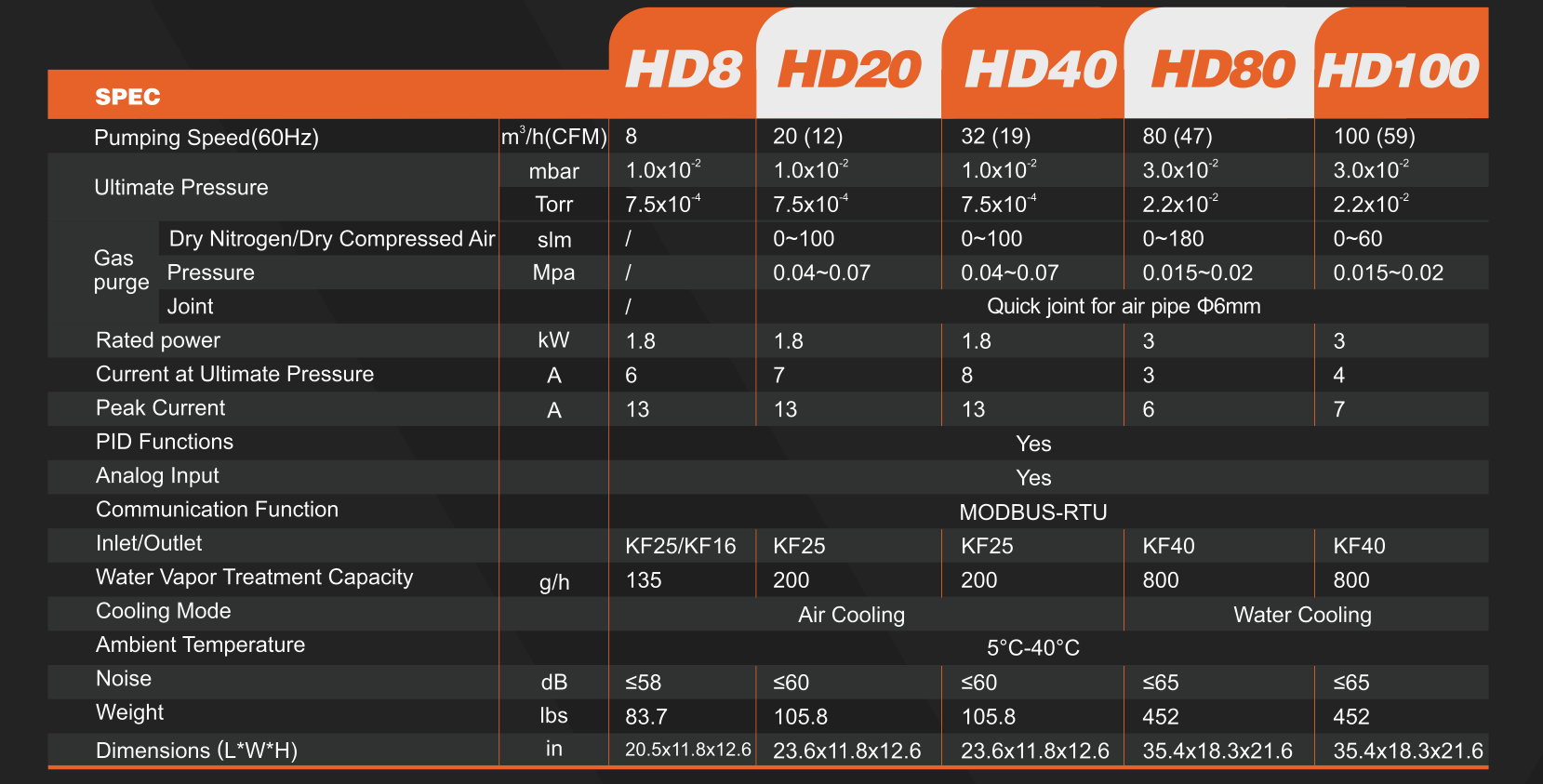

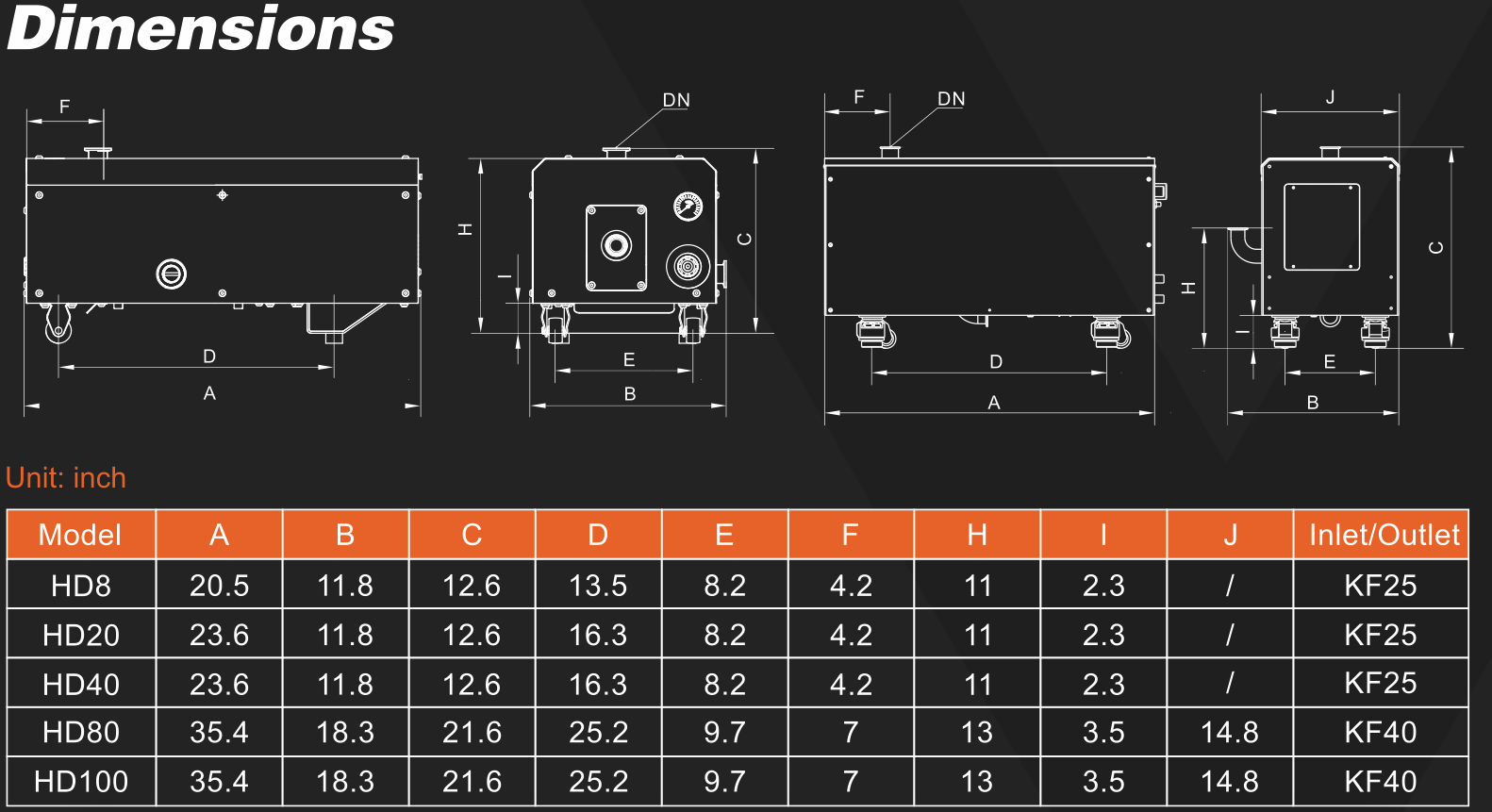

Specifications

-

Capacity Range: 8-100 m³/h]

-

Ultimate Vacuum: [8-40 m³/h 1 × 10-2mbar. (7.5× 10-4 torr), 40-100 m³/h 3 × 10-2mbar. (3.3× 10-2 torr)

-

Power Supply:115V-240V

-

Motor Power: 1.8-3.0kW

-

Water Vapor Capacity 500-800 grams/hr

Single-Stage Dry Screw Vacuum Pumps

Efficient, Reliable, and Low-Maintenance Performance for Your Industrial Needs

Overview

Our Single-Stage Dry Screw Vacuum Pumps offer a robust and highly efficient solution for industrial vacuum applications. With its innovative dry screw vacuum pump technology, this pump ensures consistent and reliable performance in demanding environments, where oil-free operation is essential. Ideal for a wide range of industries, including pharmaceuticals, chemical processing, food packaging, and more, this vacuum pump offers superior performance with minimal maintenance.

Key Features

-

Oil-Free Operation

Enjoy contaminant-free vacuum generation without the need for oil or lubrication, making it ideal for sensitive processes where contamination must be avoided. -

Energy-Efficient

Designed to optimize energy consumption, this pump delivers high performance while keeping operating costs low. -

Compact & Space-Saving Design

The compact size of the pump allows for easy integration into various systems, even in space-constrained environments. -

Low Noise Level

This pump operates with reduced noise levels, ensuring a quieter and more comfortable work environment. -

Durable & Long-Lasting

Built with high-quality materials and precise engineering, our vacuum pump is designed to withstand the rigors of continuous operation. -

Minimal Maintenance

With no oil to change and fewer moving parts compared to traditional pumps, maintenance requirements are minimal, reducing downtime and costs.

Applications

-

Pharmaceutical & Medical Industry

Ideal for processes like freeze-drying, vacuum distillation, and packaging, where contamination-free vacuum is critical. -

Chemical Processing

Suitable for handling corrosive gases and vapors in processes that require reliable, oil-free vacuum solutions. -

Food & Beverage

Perfect for food packaging and preservation processes where hygiene and contamination control are paramount. -

Electronics Manufacturing

Used in semiconductor and flat-panel display production, where consistent vacuum levels are essential.

Benefits

-

Cost-Effective

Low operating and maintenance costs over the pump's lifetime make it a cost-effective solution for your business. -

Environmentally Friendly

Being an oil-free design, it reduces environmental impact by eliminating oil disposal concerns and improving system cleanliness. -

Enhanced Performance

Provides stable and efficient vacuum performance, ensuring uninterrupted production in your operations.

How It Works

The Single-Stage Dry Screw Vacuum Pump operates on a pair of screws that rotate in opposite directions, trapping and compressing gas in the spaces between the threads. This process generates the vacuum without the need for oil or water, ensuring a cleaner and more reliable performance.